Storage Crude Oil

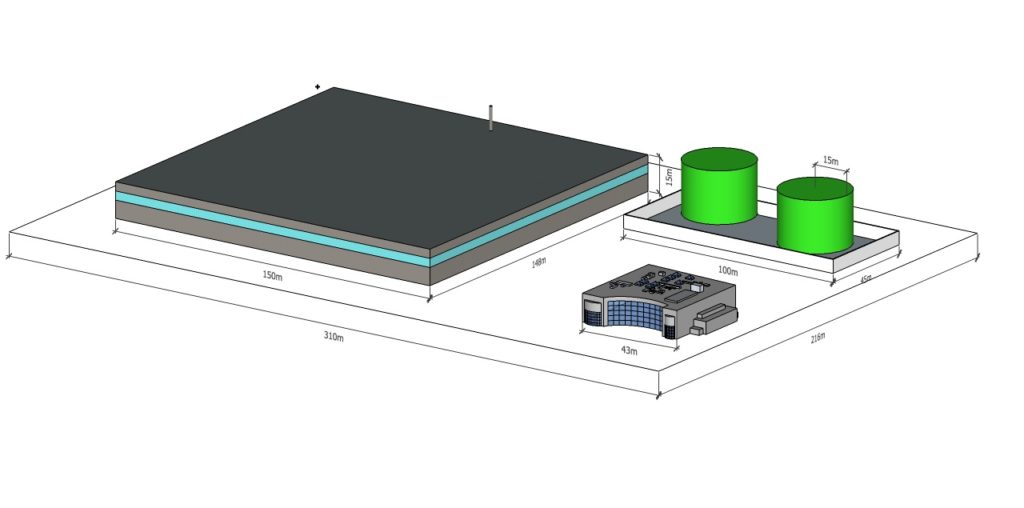

Crude oil is pumped from existing local storage tanks via pipelines to the plant and is received at a defined connection point from pipelines, passing through a metering station in two 15,000 ton buffer tanks. The existing storage on-site is sufficient to supply the refinery for 10 days with crude oil at full production.

Design Basis

O2 Blue Energy has assumed the following conditions as the design basis for both refineries.

- Annual Capacity of 9,000,000 tons of =30 API crude oil and or Extra Heavy Oil, and Refinery Bottoms

- Crude considered are coming from adjacent Pipelines

- Pipelines (3,04 wt % Sulphur)

- Conversation rate of 96% (total gasoline + diesel yield of 90 wt%, minimum 50% gasoline

- EURO VI – USA/EPA Standards

Modular Structure

Based on the above conditions, O2 Blue Energy has designed the most suitable process configuration to minimize the overall projects. This process configuration is based on the crude characterization included in the present report, but the modular projected configuration is designed to convert a wider variety of crude characteristics, such as API gravity viscosity Sulphur content.

The modular structure allows the plant to operate 365 days a year.

The process configuration will produce the following main products:

- Gasoline (Class VI) EURO-V or better

- Diesel (Class VI) Euro-V or better

No residual oil or refinery bottoms will be produced. To operate at full capacity, the plant requires:

- 9,000,000 tons of Crude oil as described below on an average daily basis of 24, 650 tons.

- 11kv Electricity Connection drawing 10MWH on average.

- Freshwater at a rate of 3,000 m3 water per day.

- Low source emissions.

This plant is equipped with a Sewage and Water purification plant as well as a garbage gasifier plant converting produced garbage into Electricity.

Modular Plant

Converting 180,000 BPD crude oil to EURO-VI standard Petrol, Diesel, and Jet-Fuel using advanced Nano Cracking Technology. Clean, Indoors

Basic Plant Layout

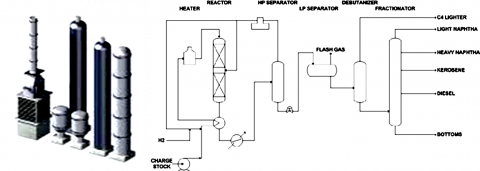

Hydrocracking

Hydrocracking is a process of catalytic cracking in the presence of Hydrogen. It uses high pressure, High Temperature. A catalyst and Hydrogen to Crack heavier feedstock into lighter, more valuable products.

Our process combines unique cracking and hydrotreating advantages we can use various types of advanced process technologies that are developed and applied to the design of hydrocracking plants. The flow schemes for the reaction system are categorized into the single-stage reaction system and two-stage reaction system, depending on the types and conversion ratio of feedstock oils and products, and the performance of the catalyst.

In general, the single-stage reactor system is used for producing kerosene and diesel oil economically, and the two-stage reactors system for cracking the feedstock oil completely and increasing the yield of middle distillate oils.

The single-stage reactor system is categorized further into the complete conversion system by recirculating the unconverted oil, and the one-through system that partially converts the oil without recirculation. The configuration will be optimized from the economics and performance.